“You can only improve what you can measure.”

By monitoring the parameters of cleanliness of the fluid, we can ascertain whether the system is operating under ideal design conditions or whether the control of contamination of the system needs to be modified. Many types of sight glasses, or level gauges, are used to check the correct volume of fluid. The shortcomings of these instruments are the reason that many causes of machine malfunctions pass unobserved.

MAIN PRODUCTS

LUNETA CMP

Luneta CMP (Control Monitoring Pod) is a multi-parameter instrument that greatly improves upon and increases the scope of one-minute inspections.

Luneta CMP is a three-dimensional sight glass that makes it possible to acquire data on the operating conditions of the fluid and to take prompt action in the case of deviation from the ideal parameters.

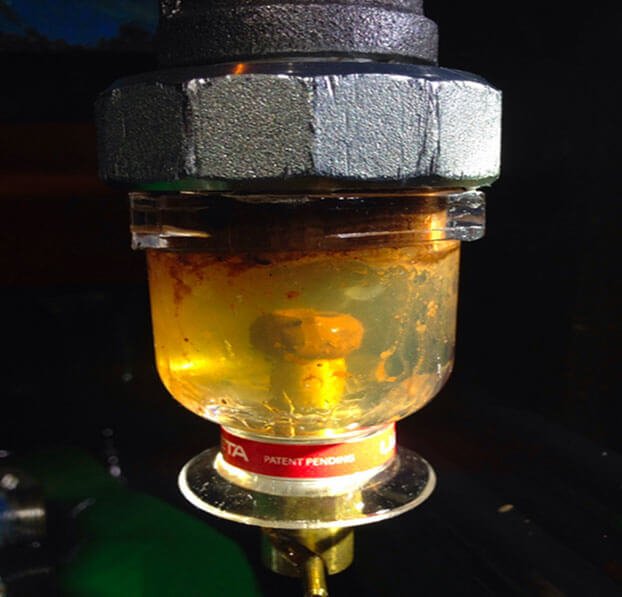

LUNETA BOWL

allows the operator to gather a greater amount of information concerning the features of the fluid: clarity, colour, presence of water and sediments. Furthermore, the neodymium magnet allows us to have a visual indication of the contamination generated by the wear processes during operation of the machine. The cup is manufactured in Tritan™ material, which makes it very resistant and suitable for use in a temperature range from -33 to +98°C . The clarity and transparency features of BOWL are not altered over time.

- Tanks / Gearboxes or Multipliers

- Hydraulic oil tank and lubrication

- Lubrication of pumps

- Low pressure systems

- Accurate fluid level measurement

- Ease of identification of change in colour of the fluid (mixing with different oil, oxidation, temperature, etc.)

- Identification of air and formation of foam

Identification of the formation of emulsions and the presence of water - Ease of inspection of the formation of metal debris with magnetic plug

- Collection of contaminants and inspection of these under the microscope with ease of access to the magnetic plug

- Collection and inspection of non-magnetic contaminants, using a convenient trap, and of sludge

- Fluid sampling valve in active area

Inspection bar for quickly checking for corrosion on metal surfaces - Quick inspection of formation of varnish deposits

- Convenient hatch for ease of sampling of fluid for quick analysis in the field, blotter tests (solids), crackle tests (water), voltage tests, etc.

- Convenient hatch for quick inspections with instruments, water sensors, dielectric constant testers, viscosity meters, etc.

- Easy removal of POD to facilitate cleaning

products menu

▽